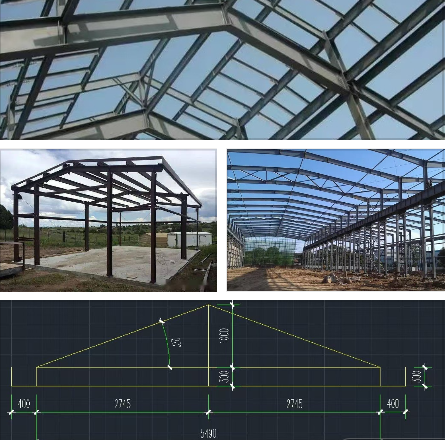

The roof of the steel structure factory must be designed with an appropriate slope, because the roof slope can not only prevent rainwater from settling in the house, thereby preventing rainwater corrosion, but also play a certain role in the roof load.

So what principles should be followed in choosing the roof slope?

1. The roof slope is generally designed according to the projected area of the sloping roof and the local rainfall. For the sloping roof of the light steel factory, the steel structure production and installation should adopt a slope of 1/8-1/20. The slope is too large, the roof frame is high, the roof frame and support consumables are more, and the wind load will be greater. The slope is too small, and the load on the roof will be greater.

The size of the slope of the gabled beam roof frame has a great relationship with the roof load.

Taking the span of 8 meters as an example, by studying the roof slope of 15 degrees, 20 degrees and 30 degrees, the force strength under the same conditions is very different.

The ridge of the roof with a slope of 15 degrees is 1.07 meters. The load on the 8-meter span herringbone beam is 10 kN, the total load-bearing capacity is 30 kN, and the support reaction force at both ends is 15 kN. Through calculation, it can be concluded that the internal force value of the upper chord is -58 kN.

The ridge of the 8-meter span herringbone beam with a 20-degree slope is 1.45 meters. Through calculation, it can be concluded that the internal force value of the upper chord is -44 kN, which saves more than 10% of the pressure compared with the 15-degree slope.

The ridge of the 8-meter span herringbone beam with a 30-degree slope is 2.3 meters, and the internal force value of the upper chord is -30 kN, which saves 28 kN compared with the 15-degree slope and 14 kN compared with the 20-degree slope.

From the above experimental values, it can be seen that the height of the slope has a huge impact on the bearing capacity of the beam. The higher the slope, the smaller the pressure. If a 15-degree slope requires 8*8 square tubes, then a 30-degree slope only requires 6*6 square tubes.

- The height difference of the roof of a general steel structure factory building is 1-3 meters. The specific operation is adjusted according to the actual situation, but it cannot exceed 5 meters. The drainage capacity of the color steel roof panel with grooves is better than that of the flat plate. The connection and joints between the plates and the walls must be coated with structural glue to avoid rain leakage.

- The steel structure factory generally chooses a slope of 1/10. Generally speaking, the higher the building, the greater the slope should be. At the same time, the factory with a larger area should also increase the slope appropriately to ensure smooth drainage.

- When choosing the slope of a steel structure factory building, it must first be combined with the national building specifications and meet the requirements of the national building specifications. At the same time, consider the stress conditions and the aesthetics of the building. Ensure that the building meets the stability and safety while achieving a certain aesthetic effect.

The slope is an important parameter of a steel structure building, and its size directly affects the building’s load-bearing capacity, wind resistance, and drainage capacity. A reasonable slope can not only ensure the stability and safety of the building, but also improve the building’s aesthetics and economic practicality.

Modern Residential Elevators: A Luxury Upgrade for SC Homes

Modern Residential Elevators: A Luxury Upgrade for SC Homes  Why More Couples Are Choosing Bespoke Engagement Rings in London – And What You Might Not Know About Man-Made Diamonds

Why More Couples Are Choosing Bespoke Engagement Rings in London – And What You Might Not Know About Man-Made Diamonds  From Classic to Contemporary: The Rise of Three Stone Lab Created Diamond Rings

From Classic to Contemporary: The Rise of Three Stone Lab Created Diamond Rings  Investing vs Saving: Why Putting Money to Work Counts

Investing vs Saving: Why Putting Money to Work Counts  What You Should Know Before Calling a Child Pornography Attorney

What You Should Know Before Calling a Child Pornography Attorney  Lab Diamonds HPHT: A Practical Buyer Guide

Lab Diamonds HPHT: A Practical Buyer Guide  Bridal Set Rings NZ Guide for Modern Couples

Bridal Set Rings NZ Guide for Modern Couples